Products

CLT SHAFT WALLS

Let Sterling Structural streamline your next construction project with our CLT Shaft Wall Kit-of-Parts. This prefabricated solution is designed to get your building up faster and more sustainably. Terralam Shaft Walls are an excellent introduction to get a taste for the benefits Mass Timber without taking the full leap – but trust us, once you see the results you’ll be ready to dive in.

Challenges with Traditional Masonry Shaft Walls

- Schedule Delays:

- Weather-dependent construction slows progress in extreme climates.

- Multiple special inspections and testing.

- Weeks long critical path construction.

- Higher Costs:

- Labor intensive with large crews.

- Multiple Trades.

- Precision Issues:

- Larger industry construction tolerances.

- Post-installed anchorage connections.

Why Choose Sterling for CLT Shaft Walls?

CLT Shaft Walls meet and exceed fire rating requirements for 1-hr and 2-hr shafts. In addition to this:

- Accelerate Your Schedule:

- Installed in hours, not weeks.

- CLT works in any climate—no weather delays.

- Simple visual inspection speeds up approval.

- Reduce Costs:

- Single-trade, fast installation.

- Factory precision minimizes rework.

- Coordination made Easy:

- Prefabrication for seamless integration.

- Continuous anchoring surfaces for flexible attachment points.

Mass Timber

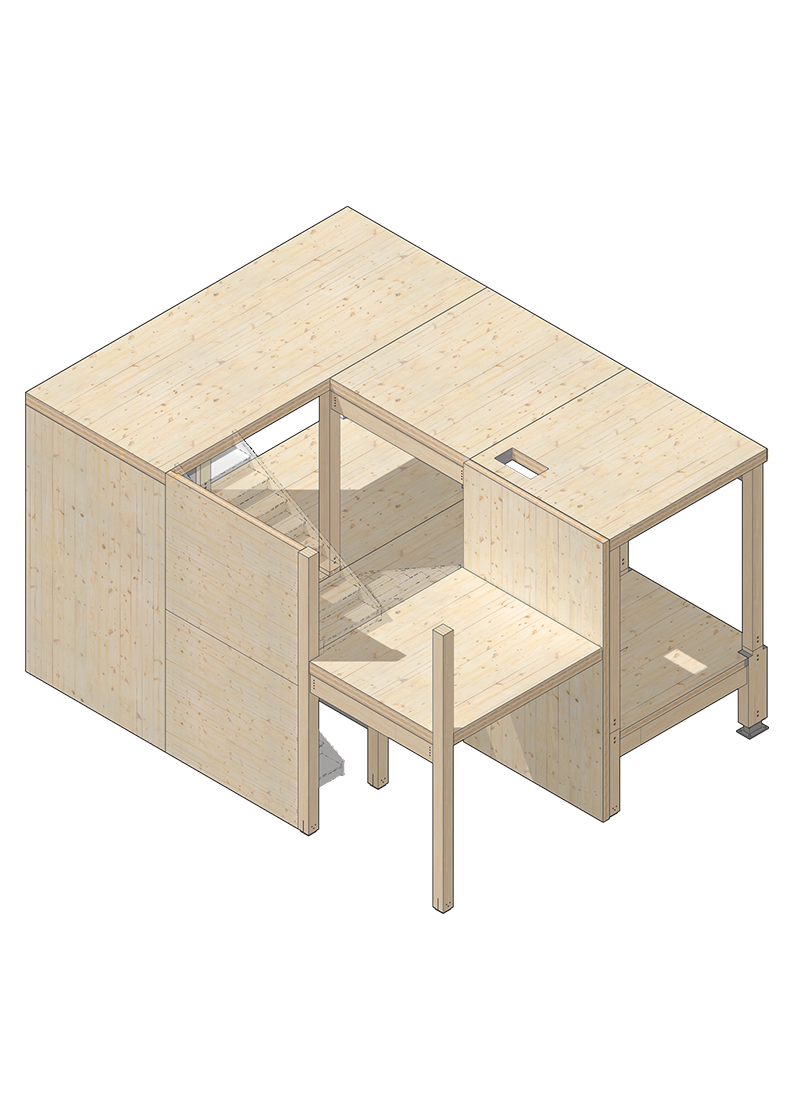

Training Mock-Up

Sterling Structural is excited to offer a small-scale mass timber building mock-up designed to educate and train installers on the fundamentals of mass timber construction. This hands-on learning tool showcases key components of prefabricated CLT and glulam systems, demonstrating best practices for installation, connection detailing, and material handling.

Built to reflect real-world construction scenarios, the mock-up provides experience that helps you gain confidence working with mass timber, in preparation for the growing demand in sustainable, high-performance building solutions. Through this initiative, we aim to strengthen workforce readiness and bridge the knowledge gap in mass timber construction techniques.

What’s Included:

- CLT Panels – The large majority of mass timber projects include CLT panels, the mock-up features both 3-ply and 5-ply CLT to familiarize teams with different panel weights and handling requirements.

- Floor & Roof Systems – Users will learn panel-to-panel spline connections that are critical to a building’s lateral strength. The mock-up includes both recessed plywood splines and surface-mounted straps, as both are common in the industry.

- Glulam Column Connections – Require different connections based on structural loads, fire rating for the super structure, and aesthetics. The kit includes column base connections to include a raised stand-off typical with concrete topping slabs.

- Glulam Beam Connections – To demonstrate more advanced connection techniques, the kit includes knife plate connections and concealed hangers, both of which require precise installation. Exposed bucket connections are not featured, as they are simpler to install and require less specialized training.