MAKING MASS TIMBER ACCESSIBLE

Our company was founded in 1949 and continues to operate according to the Sterling family values to this day. Since we are always innovating and adapting to our customers’ needs, we were one of the first companies to begin manufacturing CLT and offered its unique benefits to the site access and industrial matting market.

Today, Sterling is still America’s largest CLT manufacturer with the capacity to produce 1,000 panels a day at our plants in Lufkin, Texas and Phoenix, Illinois. In 2022 we expanded to bring our exceptional operational capacity and wealth of experience to the building construction market, with PRG 320-certified structural CLT panels available at competitive price points and timelines.

HOW WE DO IT

Sterling Structural makes mass timber accessible. We’re committed to bringing mass timber’s benefits to the wider AEC community to support building projects both large and small.

STANDARDIZED APPROACH

SPEED AND CAPACITY

ROBUST LOGISTICS

SUSTAINABLE STRUCTURE

What We Do

NOW IS THE TIME FOR TIMBER — AND WE CAN HELP

Design Assist and Coordination

Project Management and Logistics

Machining and Prefabrication

Transparent Pricing and Timelines

Value-Added Complementary Products

Sustainability Support

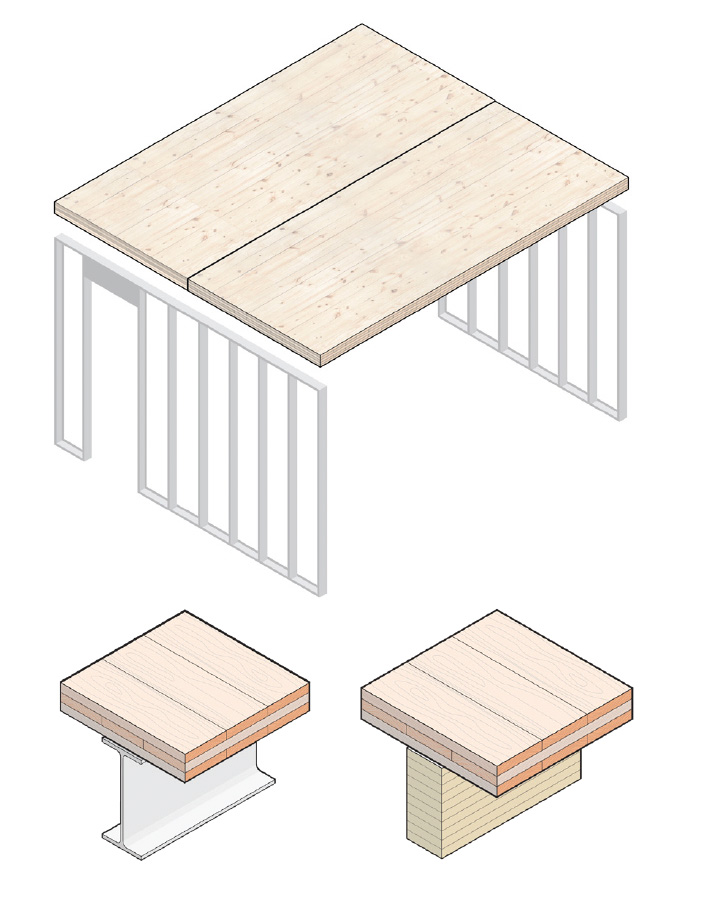

Maximize with Mass Timber Modules

Sterling Structural’s modular approach to mass timber construction makes building with this sustainable material accessible and affordable. Our standardized TerraLam CLT panels are designed for seamless integration, reducing on-site construction time and complexity. We’re ready to streamline CLT utilization while offering quality, speed and cost-effectiveness to maximize your project’s efficiency and value.

Benefits of Sterling’s standard-format panels:

- Reduced construction time

- Lower costs

- Improved quality control

- Easier transportation and logistics

- Simplified design process

- Increased flexibility for future modifications

- Reduced on-site labor requirements

- Minimized construction waste

- Better predictability in project timelines

- Easier integration of prefabricated components

SUSTAINABILITY MEETS AFFORDABILITY

Since roughly 75% of the carbon sequestered in a mass timber building is stored in its floor and roof slabs, increasing the adoption of mass timber for horizontal plate applications can significantly reduce the carbon footprint of your built environment. This approach provides flexibility for the utilization of a wider range of vertical support materials while making substantial progress in sustainability.

WHY MASS TIMBER?

- Faster Construction

- Lower Embodied Carbon

- Architecturally Elegant

WHY CHOOSE STERLING?

- Scalable, Modular Design

- Accessible Price Point

- High Volume Production

BUILD SUSTAINABLY WITH TERRALAM CLT

Made from renewable resources in the United States, our CLT minimizes greenhouse gas emissions associated with traditional construction while supporting domestic woodland and manufacturing economies. Sterling was one of the first manufacturers of CLT in North America and now has the largest capacity in the world, producing a panel every 65 seconds on our state-of-the-art, highly automated production line.

TerraLam CLT provides:

- Natural appeal and biophilic architecture

- Carbon sequestration

- Low-impact sourcing, manufacturing, and offsite fabrication

- Exceptional strength and versatility