Des Moines, IA

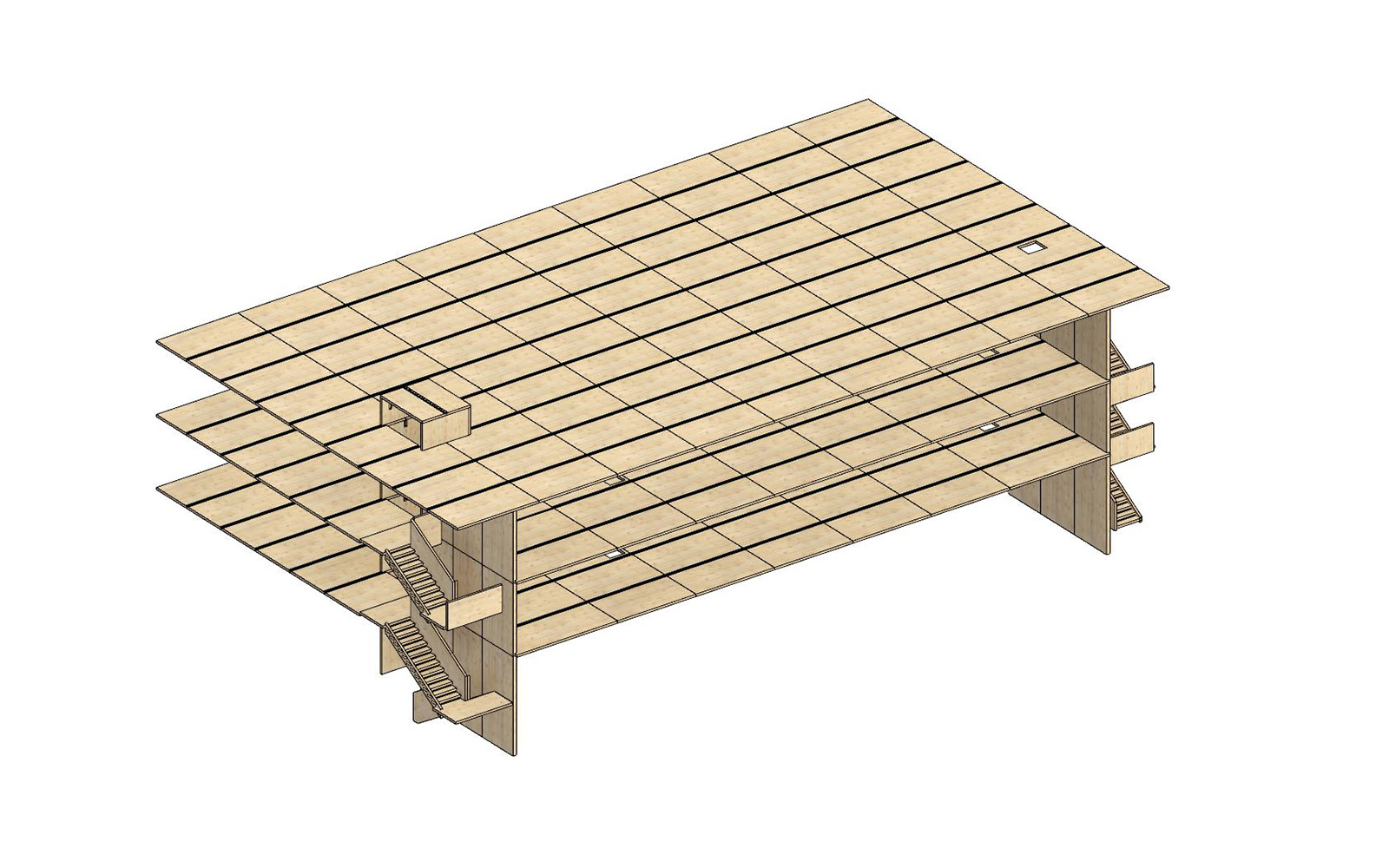

This multi-family housing project met both budget and sustainability goals by combining mass timber, including cross-laminated timber (CLT) decking and glue-laminated timber (glulam) columns and beams, with dimension lumber for a smart hybrid system. Sterling Structural also provided the prefabricated shaft walls for this project.

Mass timber brought efficiencies in terms of schedule and sequencing; it also helped the developer save money by avoiding the cost of interior drywall because the wood could be left exposed. The light-frame dimension lumber added value in other ways; it was simple for crews to frame and insulate, and the contractor was able to easily run mechanical, electrical, and plumbing (MEP) systems from floor to floor while also meeting fire resistance and acoustical design requirements. An innovative flooring assembly achieves a 55 STC/50 IIC rating while leaving the top layer as exposed concrete, providing a finished floor surface that helped the project stay on budget.

By using mass timber, the project team achieved a 70 percent reduction in embodied carbon. High efficiency MEP systems will reduce operational energy by 28 percent. Built on the site of a dilapidated gas station, Star Lofts is Iowa’s first Zero Carbon-certified building accredited by the International Living Future Institute (ILFI).

This video provides insights from the design of two mass timber multi-family projects in Des Moines, Iowa, focusing on their approach to fire-resistance and acoustics of the mass timber floor systems.

Project Stats

YEAR BUILT:

NUMBER OF STORIES:

CONSTRUCTION TYPE:

SQ FT:

Project Details

BUILDING TYPE:

Multi-Family (Apartments, Condos)

MATERIAL TYPES:

Cross-Laminated Timber (CLT)

Glulam

Stick Frame

PROJECT TEAM :

Owner/Developer: Cutler Development

Contractor/Installer: Cutler Constructions

Engineer: KPFF

Architect: ID8 Architects, PLC