Confidential

This new 160,000-square-foot facility sets a high standard for sustainable industrial development, balancing speed, efficiency, and a strong commitment to carbon reduction. Designed to support a two-shift operation, with a third shift added during peak seasons. Reducing the carbon footprint was a central driver for the project’s design and procurement strategies, including sourcing USA Southern Pine for the CLT panels—manufactured at our Phoenix plant, less than 100 miles from the project site.

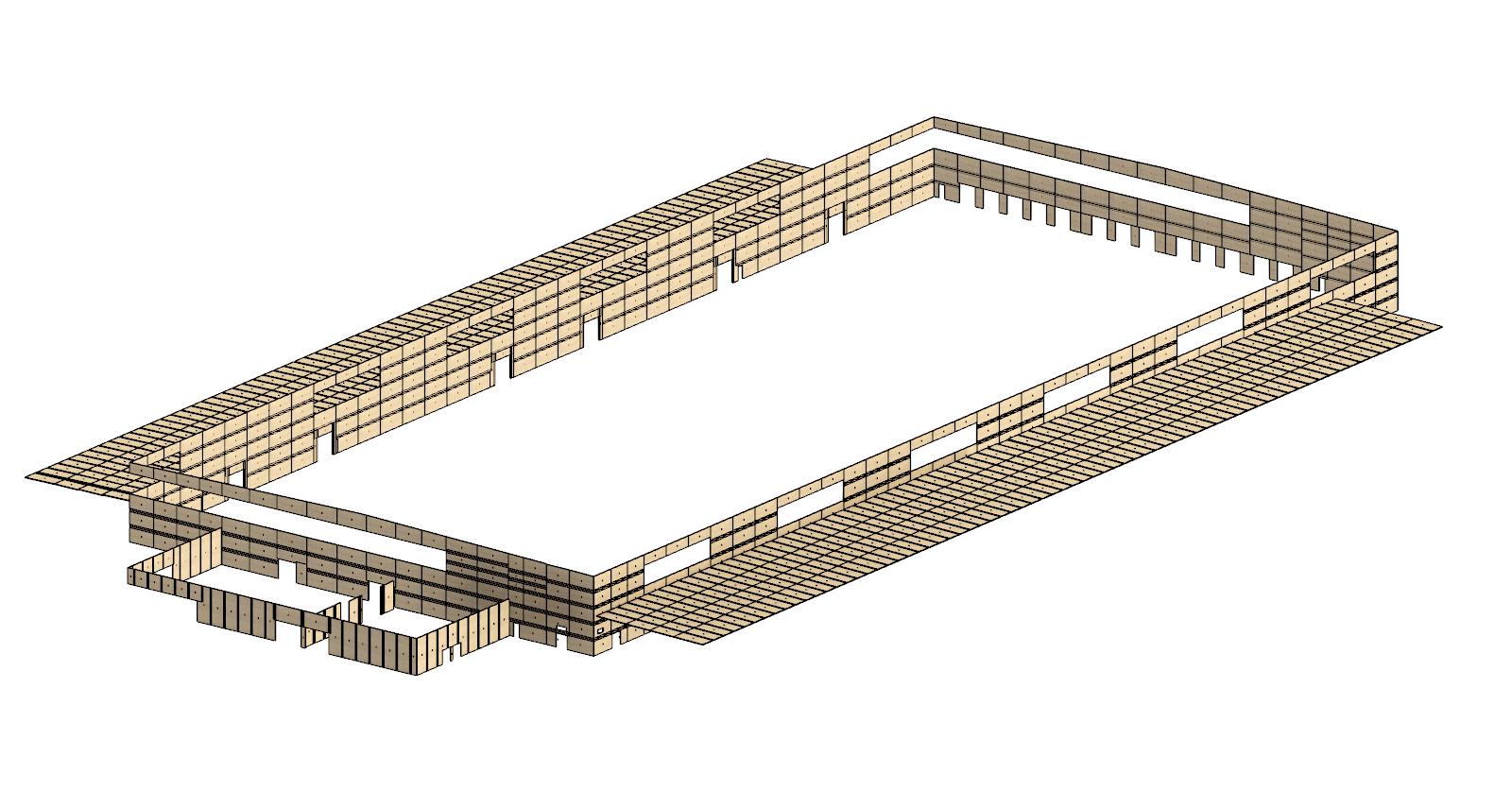

Sterling Structural supplied over 1,100 Cross-Laminated Timber (CLT) panels, forming the primary building enclosure for the main warehouse floor. Working closely with confidential structural engineer, the team developed an optimized structural grid to maximize material efficiency, particularly within the CLT wall layout. In the office bay, Sterling provided CLT panels for both the roof and walls, partnering with QB Corp for glulam components. Custom bucket connections, also supplied by Sterling, further streamlined the office bay’s erection process.

Precise installation coordination, led by a confidential installer, was critical to the success of the large and complex build. This project demonstrates the power of collaboration and innovation in sustainable industrial construction, setting a new benchmark for low-carbon logistics facilities.

Project Stats

YEAR BUILT:

NUMBER OF STORIES:

CONSTRUCTION TYPE:

SQ FT:

Project Details

BUILDING TYPE:

Storage + Business (Office)

MATERIAL TYPES:

Steel columns

Steel joist

Cross-Laminated Timber (CLT) walls

Cross-Laminated Timber (CLT) roof

Glulam columns and beams

PROJECT TEAM:

Glulam Partner: QB Corp

Connection Partner: Simpson Strong-tie

Rigging Partner: Rothoblaas

Waterproofing Partner : Vaproshield