Meet The Team

Kaye Ceille

Kevin Hsu

Michaela Harms

Marc Rivard

Sidney Filippis

Archie Landreman

Torin Kubo

Caiden DeRocher

Jacob Pincura

Amy Watson

Tom Gauthier

Candace Kao

Kyle Teal

Thomas Badger

Ryan King

Mike Gonzalez

Priscila Tammaro Novaes

Our Locations

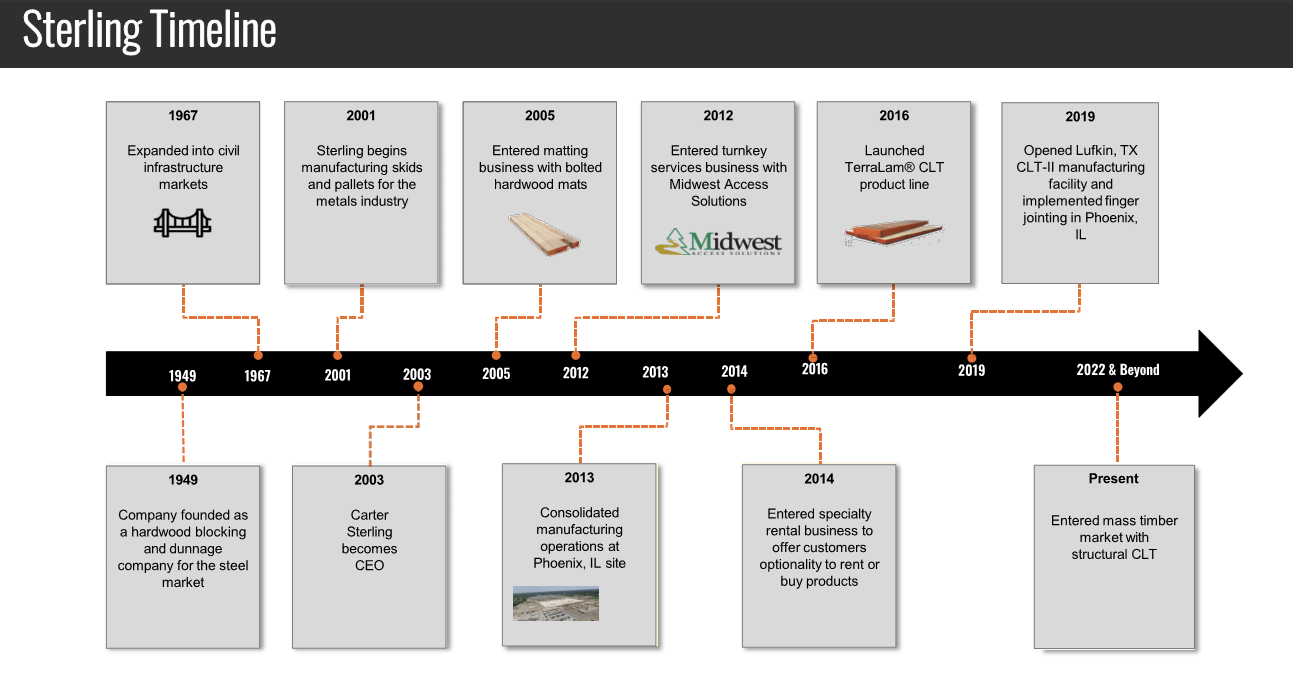

Sterling Structural leads North America in cross-laminated timber (CLT) manufacturing for the building industry. Our TerraLam® CLT panels are an innovative structural solution for construction projects of all shapes and sizes. With state-of-the-art facilities producing a panel every 65 seconds and a robust distribution network, we’re making mass timber accessible and cost-effective. Sterling’s standardized approach ensures quality and efficiency, revolutionizing sustainable building products for commercial and residential applications.

PHOENIX, IL

Sterling’s flagship factory and headquarters is located just south of Chicago, Illinois in Phoenix — a village with a rich history connected to the railroads and industrial manufacturing. Sterling repurposed this facility to become a thriving center of industry and a steady and growing source of employment for members of the community.

LUFKIN, TX

Sterling opened its second cross-laminated timber (CLT) manufacturing facility in Lufkin in 2019. Sterling leadership chose this location because of its proximity to our customers in Texas and the southern region as well as its proximity to raw materials, specifically the southern pine used to build TerraLam. It is home to a 350,000-square-foot manufacturing facility with the capacity to produce 200,000 TerraLam mats per year. It also serves as a distribution center, branch office, and the Texas office of Sterling Access Solutions.

DOWNERS GROVE, IL

After only six years in our corporate headquarters, we ran out of office space – but we aren’t done growing. Our current satellite office in Downers Grove houses members of Sterling’s Marketing, IT and Accounting teams.