A HEALTHIER ALTERNATIVE TO COMMODITY MATERIALS

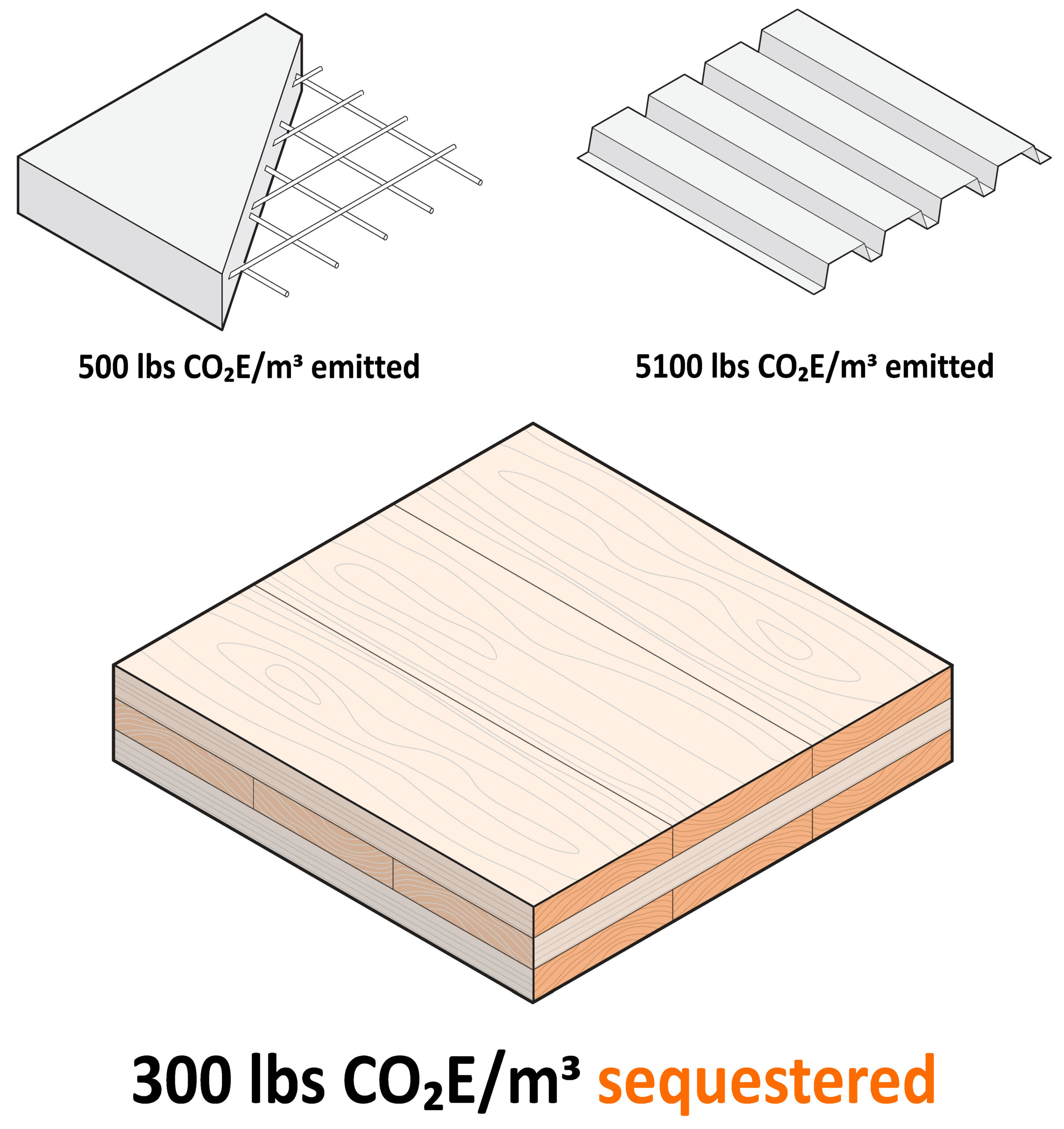

Timber buildings are healthier for the environment because wood materials store carbon throughout the life cycle of the building, instead of releasing it into the atmosphere to form carbon dioxide.

Building with forest products typically creates fewer emissions during the harvesting/extraction, manufacturing, and transportation cycle than other material types used in construction. With roughly 75% of carbon sequestered in a mass timber building being stored in floor and roof slabs, CLT in lateral applications is an excellent pathway to reducing the construction industry’s carbon footprint while leveraging the strength of engineered wood products.

CLT can play a multitude of roles in a structural system, either alongside steel and concrete in hybrid structures, or replacing them entirely: both are pathways to minimizing carbon impact in new construction. TerraLam CLT is a cost-competitive and user-friendly option that can bring structural strength and biophilic beauty into buildings of all budgets, sizes, and occupancy types.

SUSTAINABLE FORESTRY AND PROCUREMENT

TerraLam® CLT panels are built from Southern Pine, Spruce Pine Fir South or Eastern Hemlock all grown and sourced in the United States. Sterling sources high-quality pine lumber from partners in the southeastern United States who are committed to renewable growing and harvesting practices. Through domestic and responsible sourcing, Sterling supports woodland economies. Our Terralam Southern Pine products are certified to Sustainable Forestry Initiative standards.

Our raw material order volume and strategic plant location also allows lumber to be delivered directly by rail to our manufacturing facility in Phoenix, IL. Using the rail network for transport is a strategic way to reduce greenhouse gas emissions associated with supply chain freight.

MATERIAL HEALTH

DECLARE

EPD/LIFE CYCLE DATA

SUSTAINABLE FORESTRY INTIATIVE